Let’s talk about spare parts for your machines!

Contact Us!Industrial Mechanical Clutches Blog

Our blog aims to provide practical and interesting facts about machine tools, their operation and service, spare parts and accessories. It was created for future and existing customers of our company who are looking for reliable information on the correct use of machine tools.

- 2025-10-24

-

How much electricity does a universal lathe draw and how can energy consumption be effectively reduced?

Category : BLOG

Universal lathes are essential tools in workshops and industrial plants. Their efficiency and reliability are crucial for everyday work, but an equally important question is: how much electricity does a lathe draw and how can its energy consumption be optimized to prevent bills from skyrocketing? Key Points The energy consumption of lathes depends on motor

- 2025-08-22

-

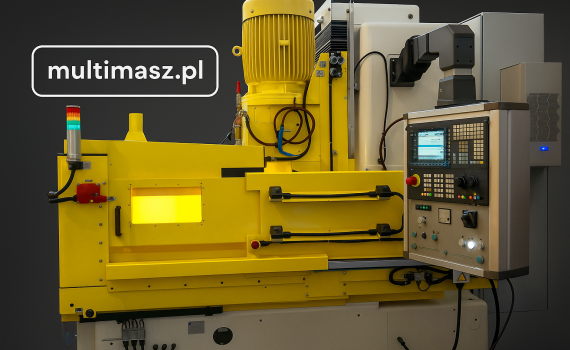

Why choose the SAB100W grinder?

Category : BLOG

In modern industrial production, where efficiency, precision, and durability are key, choosing the right machines is crucial. One such machine is the SAB100W rotary table surface grinder, which has enjoyed great recognition in production facilities for years. Key Points The SAB100W surface grinder features a large rotary table diameter (Ø1000 mm) and modern NC control,

- 2025-08-19

-

Why choose machine tools from MultiMasz?

Category : BLOG

In the world of industrial machinery, price shouldn’t be the only selection criterion, which is why MultiMasz offers much more than just a competitive product – we provide comprehensive service, safety, and real support throughout the machine’s lifespan. Key Points MultiMasz offers comprehensive service and support for its metalworking machines, ensuring reliability and peace of

- 2024-10-23

-

How to choose the right clutch for a lathe

Category : BLOG

An electromagnetic clutch allows for smooth disengagement and engagement of the drive in a lathe or other machine tool, enabling controlled movements and rotational speeds. Therefore, the right selection of a clutch is crucial for the efficiency and safety of the machine. In today’s article, we will indicate the features and applications of three types

- 2024-09-12

-

Effective cleaning of liquids and coolants from magnetic contaminants

Category : BLOG

Table of Contents Effective cleaning of liquids and coolants from magnetic contaminants is key to maintaining machine performance and product quality in many industries. Magnetic contaminants, such as metal fines, can lead to premature machine wear, reduced processing quality and increased operating costs. In this context, the use of modern purification technologies such as magnetic

- 2024-08-07

-

The role of safety guards in machine operation

Category : BLOG

Table of contents: What are the important machine safety standards Safety in the workplace is a priority for every company, especially in industry, where daily operations involve the handling of various machines. A lathe chuck guard, milling machine spindle guard or drill spindle guard is an absolute necessity in order to ensure an adequate level

- 2024-04-19

-

How to adjust electromagnetic clutch in a conventional lathe machine

Category : BLOG

Table of Contents Key Points To adjust an electromagnetic clutch in a lathe, you should identify the clutch mechanism and use the appropriate screws or nuts for fine-tuning. Regular maintenance of the clutch is crucial to ensure optimal performance of the lathe. The machine’s operating manual should always be consulted for detailed instructions on clutch

- 2023-11-09

-

How to choose the right roll-up covers for a lathe

Category : BLOG

Table of Contents What is it used for and how is a metal lathe built? How to work safely on a lathe? How to choose the right roll-up covers for a lathe Key Points Lathes are essential tools in metal machining, used for shaping various components and parts. Safety covers are crucial for protecting

- 2023-10-04

-

What are the differences between the FAT WROCŁAW TUR 50 lathe and the TUR 630 lathe?

Category : BLOG

Table of Contents What do you need to know about the TUR 50 lathe? What makes the TUR 630M lathe unique? Key Points TUR 50 and TUR 630M lathes are universal machines manufactured by the “PONAR” Automatic Lathe Factory in Wrocław, known for their high quality and value in metal machining. The TUR 50 lathe

- 2023-09-18

-

What is the principle of operation of clutch and brake plates (discs)?

Category : BLOG

Table of Contents What types of clutch and brake plates (discs) are there? When and how to replace the clutch plates? Clutch and brake plates are used to transfer torque from the driving part to the driven part of the device. Clutch plates are placed in clutches or brakes, which, depending on the way the

T